-Techniques-

DSC Analysis

Differential Scanning Calorimetry (DSC) is a thermal analysis technique used to measure changes in heat flows associated with material transitions.

DSC measurements provide both qualitative and quantitative data on endothermic (heat absorbing) and exothermic (heat evolving) processes. DSC is commonly used to determine the glass transition temperature and crystalline melting point of polymeric materials. This technique can also be used to determine the percent crystallinity of a polymer, oxidative induction time (OIT) of a material, heat of reaction, and normal boiling point.

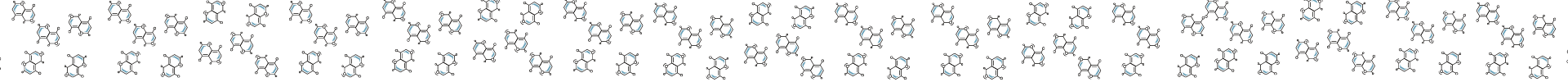

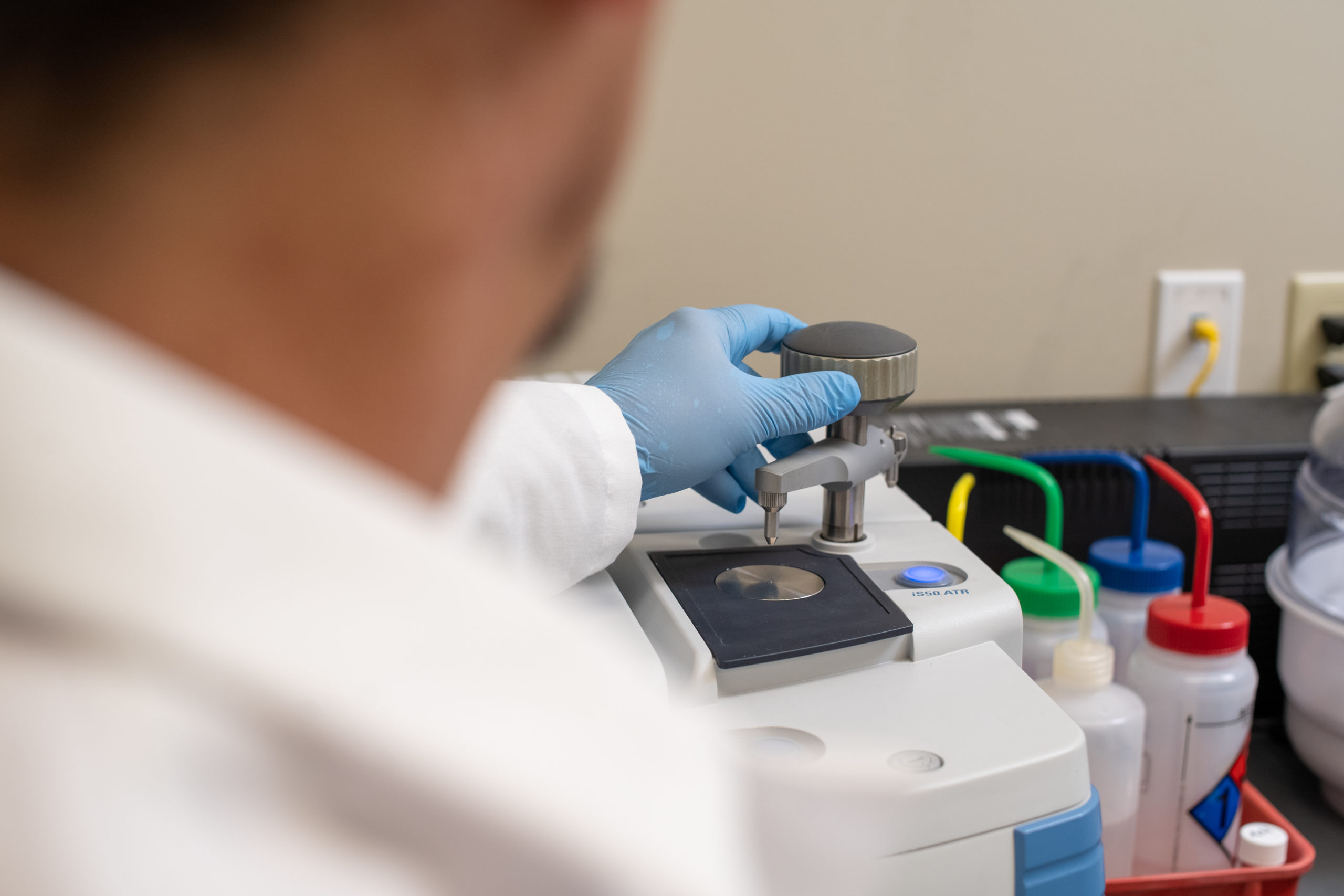

A simplified explanation of a DSC sample evaluation may be described as follows. A material specimen is weighed and placed into a DSC sample pan. The sample pan and an empty reference pan are placed within the DSC apparatus. The DSC cell is heated or cooled at some controlled rate while continuously monitoring the differential heat flow between the sample and reference pans. The heat flow profile obtained during the DSC heating or cooling run is subsequently analyzed for any of several endothermic and/or exothermic transitions.

Examples

- The DSC technique can be used to make qualitative statements about whether or not polymer blend systems are miscible or immiscible, provided the inherent homopolymer transition temperatures of the blend components are sufficiently well separated. A description of the glass transition temperature Tg characteristics of two different polymer blend systems evaluated by DSC will illustrate this point. Polymer blends based on polystyrene (Tg = 100°C) and poly dimethyl phenylene oxide (Tg = 210°C) are miscible in all proportions. DSC thermal profiles of various PS/PDMPO blend compositions show only a single glass transition temperature, located somewhere between 100°C and 210°C, dependent upon the relative weight fractions of the homopolymer components within the blend. In contrast, polymer blends based on polystyrene and polyisoprene (Tg = -70°C) are immiscible. PS/PI blends and exhibit distinct phase separated domains and show two characteristic glass transition temperatures in the same temperature ranges as their respective homopolymer blend components. In summary, polymer blend systems which show two Tgs by DSC are recognized as being immiscible; those which show only a single Tg may or may not be miscible.

- Teflon™ samples are manufactured using different processing conditions, which directly influence the extent of crystallinity in the finished parts. Using the heat of fusion of an ideal, 100% crystalline sample, the percent crystallinity of manufactured samples may be determined by DSC. Specifically, a Teflon™ sample was heated in a DSC cell and showed a characteristic endothermic melting peak. The peak area was normalized and integrated to quantify the experimental heat associated with the crystalline melting process. By comparing the experimental heat value to that of a theoretical, 100% crystalline sample, the percent crystallinity of the sample was determined.

Related Testing Techniques

Ready to Get Started?

Give us a call and speak with an actual scientist.